|

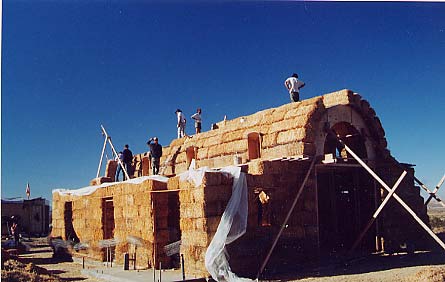

vault project main page  Morning in the desert before the vault raising. The vertical walls and the bond beam on top of them were in place. Plywood falsework was erected. Bales, water and food are on hand.  Horizontal rebar spreads the load from tie wires along the mesh. The inside bar was notched into place on the falsework, and the mesh was wrapped over....  Creating a big birdcage. The 2" x 2" wire mesh was tied to the rebar. The same rebar/mesh layer would later be placed on the outside of the vaults, and the tension wires would be inserted between bale courses and tied inside and out (see diagram)  Boards were stretched across the buttress and bedroom walls to provide staging for placing the bales. Most of the first day was spent running mesh and clamping the first course of bales to the bond beam.  Pulley cranes were erected on each side of the vault, bales were hooked and pulled up onto the staging level, then set into place. Raising the bales was one of the most popular jobs.  Owner Lou Harrison and some of the crew of volunteers.  Janet Johnston, project architect and Sabina, Dog-on-Site, take a short break once the baling crews had learned their jobs and hit their stride.  Work on the second day progressed rapidly.  Janet and George set one of the last bales.  By sundown the second day, the vault was complete.  Lou in the (shady) bale tying headquarters. more |

||

|